Detailed Explanation of the Manufacturing Process for WPC Wall Panels

Introduction to WPC Wall Panels

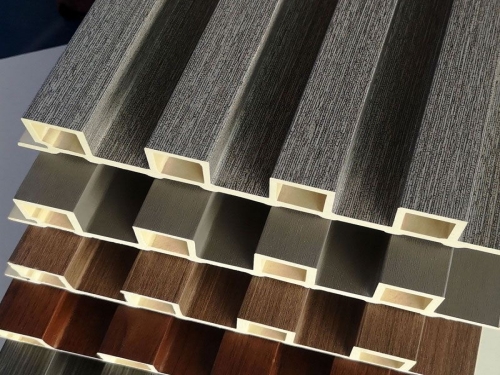

Wood Plastic Composite (WPC) wall panels represent a cutting-edge fusion of natural wood aesthetics and modern plastic durability. These panels, widely produced by WPC wall panel manufacturers, combine wood fibers with thermoplastics to create a sustainable, versatile material suitable for both indoor and outdoor use. The wall panel manufacturing process is a sophisticated blend of technology and craftsmanship, ensuring the panels are moisture-resistant, termite-proof, and visually appealing. This article offers an in-depth look at how these panels are made, spotlighting the expertise of China WPC wall panel manufacture leaders like Woocan Company. Whether you’re a designer, builder, or buyer, understanding this panel process unveils the innovation behind this eco-friendly solution.

What is WPC Material?

WPC material is a hybrid blend of wood fibers—often sourced from recycled sawdust or wood scraps—and thermoplastics like polyethylene (PE) or polyvinyl chloride (PVC). This combination, perfected in a WPC wall panel factory, delivers a product that mimics wood’s warmth while boasting plastic’s resilience. Typically, the mix is around 60% wood and 40% plastic, though ratios vary based on desired strength or flexibility. Additives like UV stabilizers and colorants enhance durability and aesthetics. As a sustainable choice, WPC material reduces waste by repurposing resources, making it a favorite among eco-conscious WPC wall panel suppliers and a staple in green construction projects worldwide.

The Role of WPC Wall Panel Manufacturers

WPC wall panel manufacturers are the backbone of this industry, transforming raw WPC material into functional, stylish panels. These experts, including top-tier WPC wall panel factories like Woocan Company, oversee every stage—from material sourcing to final production. They innovate designs, ensure quality, and cater to diverse client needs with customizable options like textures and colors. Beyond production, manufacturers provide installation guidance and support, vital for maximizing panel longevity. Their adherence to strict standards, such as durability and fire resistance, ensures reliability. Partnering with a reputable China WPC wall panel manufacture guarantees products that blend practicality with aesthetic appeal for any project.

Overview of the WPC Wall Panel Manufacturing Process

The wall panel manufacturing process for WPC panels is a multi-faceted journey that demands precision. It starts with raw material preparation, followed by blending, extrusion, cooling, and finishing. Each step in this panel process, executed in a WPC wall panel factory, shapes the material into durable, attractive panels. Wood fibers and thermoplastics are mixed into a uniform composite, extruded into specific profiles, cooled to solidify, and treated for enhanced appearance. Leading WPC wall panel suppliers like Woocan Company refine this process with advanced machinery and quality checks, ensuring the final product meets global standards and satisfies diverse architectural demands.

Step-by-Step Guide to WPC Wall Panel Production

Step 1: Raw Material Selection

The panel process begins with choosing high-quality wood fibers and thermoplastics. WPC wall panel manufacturers source sustainable wood, often recycled, and select plastics like PP or PVC based on performance needs. Additives are picked for specific enhancements, such as weather resistance.

Step 2: Material Preparation

Wood is ground into fine powder, and plastics are prepped for melting in a WPC wall panel factory. This ensures seamless blending, with impurities filtered out to avoid flaws in the final product.

Step 3: Mixing and Compounding

In this critical stage, materials are blended in precise ratios using high-speed mixers. Heat binds the components, forming a consistent mix that defines the panel’s quality.

Step 4: Extrusion and Molding

The mixture enters an extruder, where heat and pressure shape it into panels. This step, central to wall panel manufacturing, allows for varied designs tailored to client specifications.

Step 5: Cooling and Solidification

Panels are cooled via water or air systems to lock in their shape, preventing distortion—a key focus for WPC wall panel suppliers ensuring structural integrity.

Step 6: Surface Finishing

Surface treatments like sanding or embossing enhance texture and durability, often mimicking natural wood, a hallmark of China WPC wall panel manufacture expertise.

Step 7: Quality Control and Inspection

Rigorous testing for strength, color consistency, and size accuracy ensures only top-tier panels leave the WPC wall panel factory.

Step 8: Packaging and Distribution

Panels are carefully packaged and shipped, maintaining quality from factory to site, a priority for every WPC wall panel supplier.

Types of WPC Wall Panels and Their Applications

WPC wall panels vary by purpose, each crafted uniquely by WPC wall panel manufacturers:

Interior Panels: Perfect for homes and offices, offering design versatility.

Exterior Panels: Built for weather resistance, ideal for cladding and fencing.

Decorative Panels: Eye-catching options for retail and hospitality spaces.

Acoustic Panels: Noise-reducing solutions for studios and auditoriums.

Fire-Retardant Panels: Enhanced safety for public buildings.

These applications highlight the adaptability of products from a China WPC wall panel manufacture like Woocan Company.

Advantages of WPC Wall Panels Over Traditional Materials

WPC panels outshine wood or concrete with durability, low maintenance, and eco-friendliness. Produced in a WPC wall panel factory, they resist rot and fading, require minimal upkeep, and leverage recycled materials—benefits championed by WPC wall panel suppliers like Woocan Company.

Quality Control in WPC Wall Panel Manufacturing

Quality is paramount in wall panel manufacturing. WPC wall panel manufacturers inspect raw materials, monitor production, and test finished panels for durability and compliance, ensuring excellence from every WPC wall panel factory.

Woocan Company: A Leading WPC Wall Panel Supplier

Woocan Company, a standout China WPC wall panel manufacture, excels with its advanced facility and diverse offerings. From interior to exterior panels, their products grace homes, hotels, and offices globally, backed by stellar customer service (woocanwood.com).

Key Questions International Buyers Should Ask Chinese Suppliers

When sourcing from a WPC wall panel supplier, ask:

What’s the material composition?

Are certifications available?

Can I get samples?

What’s the lead time?

Are customizations offered?

These ensure quality from a China WPC wall panel manufacture.

Conclusion

The wall panel manufacturing process for WPC panels showcases precision and innovation, delivering sustainable, durable solutions. With leaders like Woocan Company, WPC wall panel manufacturers continue to redefine construction standards, offering buyers unmatched quality and versatility.